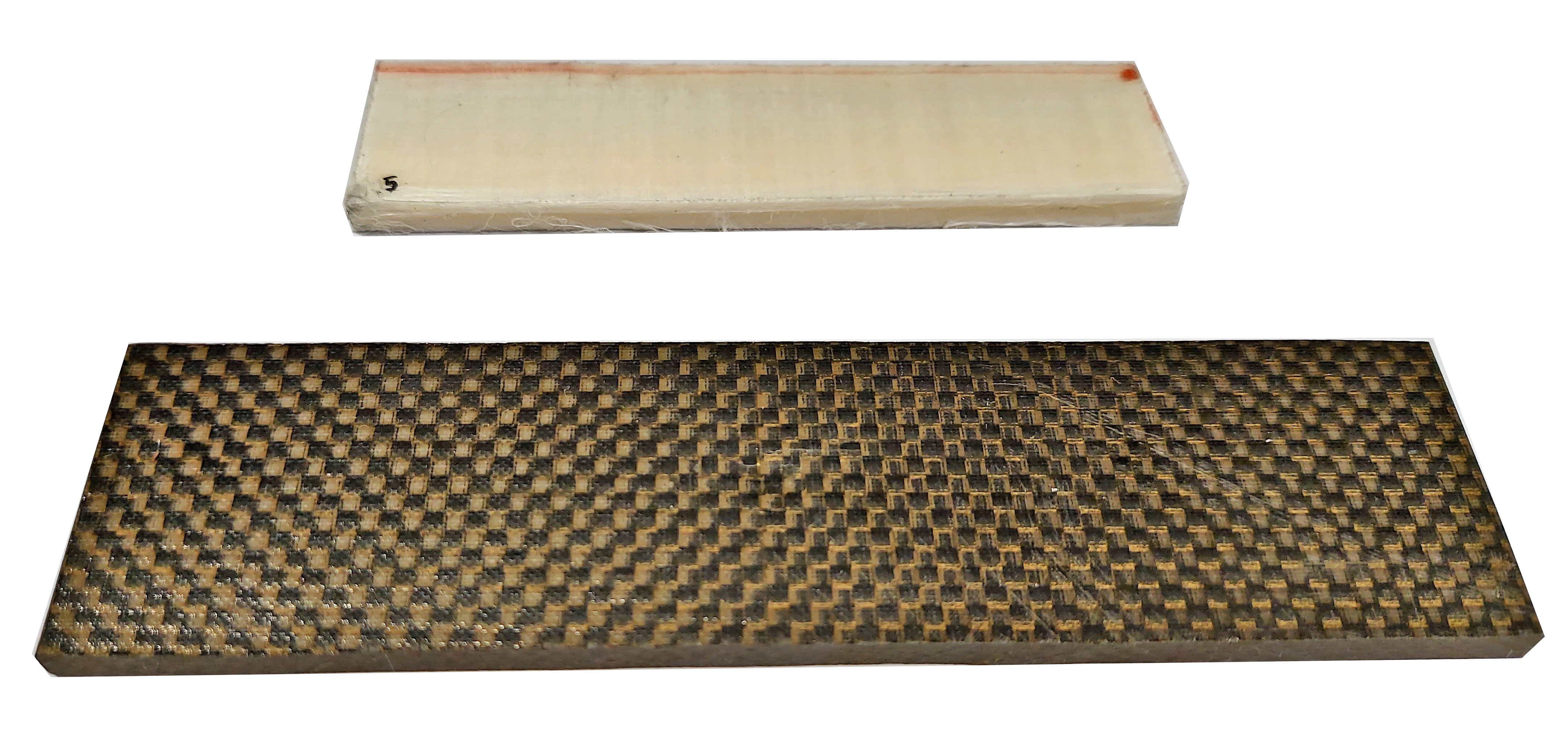

Testing of composites and wood

Sonelastic® Systems allow the non-destructive and highly accurate determination of the modulus of elasticity and damping of composites, woods and by-products. They are systems with an excellent cost-benefit ratio and applicable to a wide range of geometries and dimensions, allowing to test cylinders, rectangular bars, discs and rings with dimensions between 15 mm and 5.3 meters.

Sonelastic® Systems employ the Impulse Excitation Technique and comply with ASTM E1876-22, which recommends testing anisotropic materials only after careful consideration of the anisotropy effects on elastic properties. The characterization of anisotropic materials usually involves the preparation of more than one specimen according to the symmetry of the material. For more information on the preparation and testing of composite specimens, see the white paper Determination of composites elastic moduli using the Impulse Excitation Technique. For more information on the preparation and testing of wood and byproducts specimens, see the white paper Determination of wood and byproducts elastic moduli using the Impulse Excitation Technique.

Applications

Sonelastic® Systems have a wide range of applications in the development and quality control of composite materials, wood and byproducts, such as:- Determination of elastic moduli and damping;

- Process optimization;

- Quality control;

- Curing and drying monitoring;

- Refinement of simulations using the Finite Element Method (FEM/FEA);

- Classification and detection of defects;

- Weather-induced degradation studies.

Sonelastic® Systems applications examples

Application: Testing of composites used in the manufacturing of wind turbines.

Application: Research and development of polymers and composite materials.

Contact person: Prof. Sandro Campos Amico.

Application: Research and development of composites for aerospace applications.

Contact person: Prof. Edson Cocchieri Botelho.

Application: Classification and characterization of wood.

Contact person: Eng. Luciano Roitman.

Application: Research and development of wood derivatives.

Contact person: Prof. Gustavo Henrique Denzin Tonoli.

Application: Classification and characterization of wood.

Contact person: Prof. Pedro Segundinho.

Application: Characterization of the elastic modulus of bamboos and derivatives.

Contact person: Prof. Khosrow Ghavami.

Application: Classification and characterization of wood.

Contact person: Profa. Virginia Giacon.

Application: Evaluation of the sound of native woods for musical instruments.

Contact person: Prof. Estevão Monteiro de Paula.

Publications employing the Sonelastic® Systems

F.A. Guimarães, V.A. Guimarães, F. Goedel, N.L. Batista, F.A. Silva, M.L. Costa, E.C. Botelho. Mechanical performance of Continuous/Short carbon Fiber-Reinforced Poly(phenylene sulfide) composites. Engineering Failure Analysis, Volume 141, 2022, 106613, ISSN 1350-6307, https://doi.org/10.1016/j.engfailanal.2022.106613.

L. F. P. Santos, C. E. Moraes, T. R. Amaral, M. R. da Silva Silveira, C. A. Ferreira, B. Ribeiro, M. L. Costa, E. C. Botelho, Influence of carboxylated multi-walled carbon nanotube on the thermostability, and viscoelastic properties of poly (ether imide)/carbon fiber laminates. Diamond and Related Materials, Volume 126, 2022, 109113, ISSN 0925-9635, https://doi.org/10.1016/j.diamond.2022.109113.

Angrizani CC, de Oliveira BF, Lorandi NP, Ornaghi HL, Amico SC. Combined hygrothermal aging and mechanical loading effect on unidirectional glass/epoxy composites. Polymers and Polymer Composites. 2022;30. doi:10.1177/09673911221095261

A. Azadeh, K. Ghavami, J. J. García. The influence of heat on mechanical properties of Dendrocalamus giganteus bamboo. Journal of Building Engineering, Volume 43, 2021, ISSN 2352-7102, https://doi.org/10.1016/j.jobe.2021.102613.

R. F. S. Ribeiro, J. F. S. Feiteira, J. P. Gouvêa, A. F. Ferreira. Experimental Investigation on Variability in Properties of Amazonian Wood Species Muiracatiara (Astronium lecointei) and Maçaranduba (Manilkara huberi) Focusing Guitar Fingerboards Manufacturing. Journal of Bioresources and Bioproducts, 2021, 6(1): 33-38. doi: 10.1016/j.jobab.2021.02.006.

J. Santos, R. Tucunduva, J. d’Almeida. Mechanical Characterization of PA 12 and HDPE Pipes Before and After Aging in Water at Two Different Temperatures. International Journal of Research -GRANTHAALAYAH, 9(1), 248–256, (2021). https://doi.org/10.29121/granthaalayah.v9.i1.2021.2973.

M. M. A. D. Maciel, M. Y. Shiino, H. J. C. Voorwald, M. O. H. Cioffi. Residual modulus degradation model for woven fabric composite determined by impulse excitation technique. International Journal of Fatigue, Volume 133, 2020, ISSN 0142-1123. https://doi.org/10.1016/j.ijfatigue.2019.105456.

D. L. Faria, T. A. Lopes, M. V. Scatolino, T. P. Protásio, M. F. Nascimento, F. A. R. Lahr, L. M. B. Mendes, J. B. G. Júnior. Studying the grammage in lvl panels glued with castor oil-based polyurethane adhesive: a possible alternative to formaldehyde releasing adhesives. CERNE, v. 26, n. 1, p.140-149, 2020.

D. L. Faria, T. A. Lopes, M. V. Scatolino, J. Soriano, L. M. Mendes, J. G. Júnior. Static bending of glulam beams manufactured with rubber wood and epoxy adhesive. Revista Matéria, 25(3), 2020, ISSN 2317-6342.

D. L. Faria et al. Physical and mechanical behavior of glulam beams produced with rubberwood treated with preservatives. Ciência e Agrotecnologia, v. 44, 2020. https://doi.org/10.1590/1413-7054202044012020.

FARIA, D.L.; CRUZ, T.M.; MESQUITA JUNIOR, L.; DUARTE, P. J.; MENDES, L. M.; GUIMARAES JUNIOR, J. B. Number of laminae on the mechanical behavior of glued laminated timber (glulam) of Toona ciliata produced with vegetable polyurethane adhesive. CIÊNCIA E AGROTECNOLOGIA (ONLINE), v. 43, p. 1-8, 2019. https://dx.doi.org/10.1590/1413-7054201943014819

OTANI, L. B., Amico, S.C., TRINDADE, R.S., PEREIRA, A.H.A. Characterization of the elastic moduli of composite materials by the impulse excitation technique. In: 2nd Brazilian Conference on Composite Materials - BCCM, 2014, São José dos Campos/SP. 2nd Brazilian p. 1-6. https://www.researchgate.net/publication/301198692

QUINAYÁ, D.C.P., D’ALMEIDA, J.R.M. Nondestructive characterization of epoxy matrix composites reinforced with Luffa lignocellulosic fibers. Materia-Rio de Janeiro, v. 22, p. e11848, 2017. http://dx.doi.org/10.1590/s1517-707620170002.0181

BATISTA, N.L., OLIVIER, P., BERNHART, G.; REZENDE, M.C.; BOTELHO, E.C. Correlation between degree of crystallinity, morphology and mechanical properties of PPS/carbon fiber laminates. Materials Research, v. 19, p. 195-201, 2016. http://dx.doi.org/10.1590/1980-5373-mr-2015-0453

ROJA, J.A., RIBEIRO, B., REZENDE, M.C. Influence of serrated edge and rectangular strips of MWCNT buckypaper on the electromagnetic properties of glass fiber/epoxy resin composites. Carbon, Volume 160, 30 April 2020, Pages 317-327. https://doi.org/10.1016/j.carbon.2020.01.036

LOPES, B.J., DA SILVA, G.A.S., D’ALMEIDA, J. R. M. Evaluation of the Residual Strength of a Polyester/E-Glass Composite Tray After Exposure to High Temperatures Due to a Nearby Fire Event. Fire Technology 2018. https://doi.org/10.1007/s10694-018-0726-y

N. L Batista, K. Iha, E. C Botelho. Evaluation of weather influence on mechanical and viscoelastic properties of polyetherimide/carbon fiber composites. Journal of Reinforced Plastics and Composites Vol 32, Issue 12, pp. 863 – 874 April-30-2013. http://dx.doi.org/10.1177/0731684413482994

J. H. S. Almeida, S. C. Amico, E. C. Botelho, F. D. R. Amado. Hybridization effect on the mechanical properties of curaua/glass fiber composites. Composites Part B: Engineering, Volume 55, 2013, Pages 492-497. ISSN 1359-8368. http://dx.doi.org/10.1016/j.compositesb.2013.07.014

J. H. S. Almeida, C. C. Angrizani, E. C. Botelho, S. C. Amico. Effect of fiber orientation on the shear behavior of glass fiber/epoxy composites. Materials & Design (1980-2015), Volume 65, 2015, Pages 789-795. ISSN 0261-3069, http://dx.doi.org/10.1016/j.matdes.2014.10.003

BATISTA, Natassia Lona et al. Correlation between degree of crystallinity, morphology and mechanical properties of PPS/carbon fiber laminates. Mat. Res.. 2016, vol.19, n.1, pp.195-201. ISSN 1516-1439. http://dx.doi.org/10.1590/1980-5373-MR-2015-0453

H. O. Silva, A. Andrianov, M. N. B. Júnior. Evaluation of the structural behavior of aluminum honeycomb sandwich panels for microsatellites. Proceedings of the CILAMCE 2016 - XXXVII Iberian Latin-American Congress on Computational Methods in Engineering, ABMEC, Brasília, DF, Brazil, November 6-9, 2016.

A. R. Feiferis and J. R. M. d’Almeida. Evaluation of Water Absorption Effects on the Mechanical Properties and Sound Propagation Behavior of Polyester Matrix- Sponge Gourd Reinforced Composite. Journal of Composites and Biodegradable Polymers, 2016, 4, 26-31. http://dx.doi.org/10.12974/2311-8717.2016.04.01.4

L. R. S. Pereira, T. T. Maldonado; R. C. Alves, E. V. M. Carrasco. Estimativa do módulo de elasticidade em função da temperatura utilizando ondas de excitação. Anais do XV EBRAMEM - Encontro Brasileiro em Madeiras e em Estruturas de Madeira 09-11/Mai, 2016.

G. G. Cezário, B. A. G. C. Ferreira, D. W. Silva, A. P. Vilela, L. M. Mendes, R. F. Mendes. Efeito de diferentes tipos de revestimento na avaliação do módulo de elasticidade dinâmico em painéis MDF. Anais do XV EBRAMEM - Encontro Brasileiro em Madeiras e em Estruturas de Madeira 09-11/Mai, 2016.

Otani, L.B., Pereira, A.H.A.. Caracterização dos módulos elásticos de compósitos utilizando a Técnica de Excitação por Impulso - Informativo técnico-científico ITC-06. ATCP Engenharia Física, Divisão Sonelastic. Revisão 1.3, 18/12/2014. http://dx.doi.org/10.13140/RG.2.1.2599.8248

Otani, L.B., Segundinho, P.G.A., Morales, E.A.M., Pereira, A.H.A.. Caracterização dos módulos elásticos de madeiras e derivados utilizando a Técnica de Excitação por Impulso. ATCP Engenharia Física, Divisão Sonelastic. Revisão 1.3, 25/02/2015. http://dx.doi.org/10.13140/RG.2.1.4647.8242

Discover the Sonelastic® Systems:

Sonelastic® system for small specimensSonelastic® system for medium specimens

Sonelastic® system for large specimens

Sonelastic® Custom System and quotation