Testing of metals, alloys and coatings

Sonelastic® Systems are a fast and non-destructive solution with excellent cost-benefit ratio for elastic moduli characterization of metals, alloys and coatings. They are applicable to a wide range of geometries and dimensions, allowing to test cylinders, rectangular bars, discs and rings with dimensions between 15 mm (≈ ½ in) and 5.3 meters (≈17 ft).

Sonelastic® Systems employ the Impulse Excitation Technique for the non-destructive determination of the elastic modulus of metallic materials according to the ASTM E1876 standard. Variations of elastic moduli reveal information about the microstructure, presence and evolution of defects in these materials.

Applications

Sonelastic® Systems have a wide range of applications in the characterization, development and quality control of metallic materials and coatings:- Study of microstructural changes influence on the elastic properties;

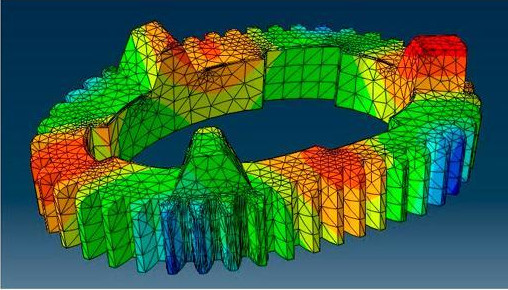

- Refinement of finite element method analyzes (FEA/FEM);

- Monitoring quenching and tempering processes;

- Refinement of creep and fatigue tests;

- Development of biocompatible alloys with low modulus of elasticity;

- Characterization of thermal and plasma spray coatings.

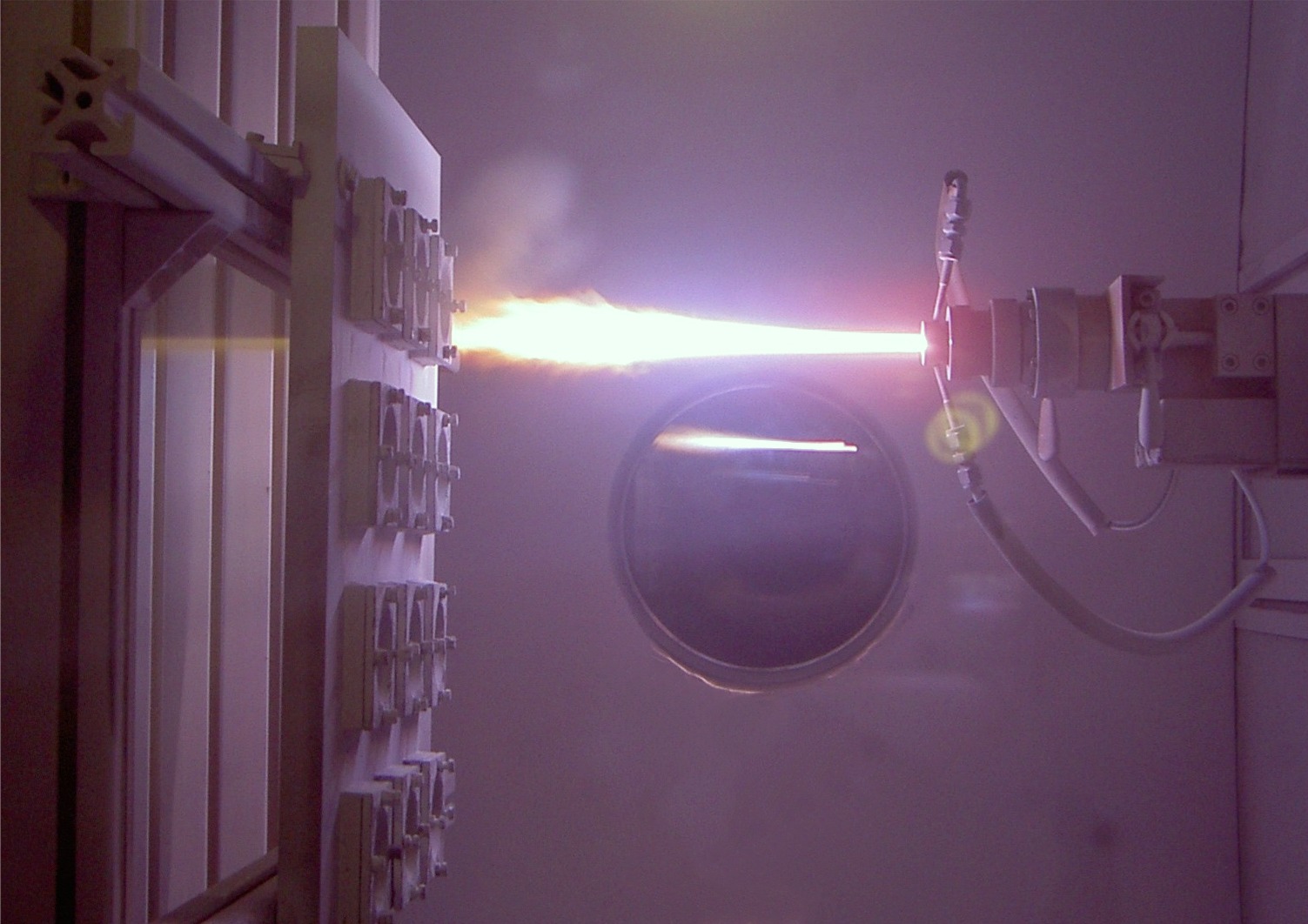

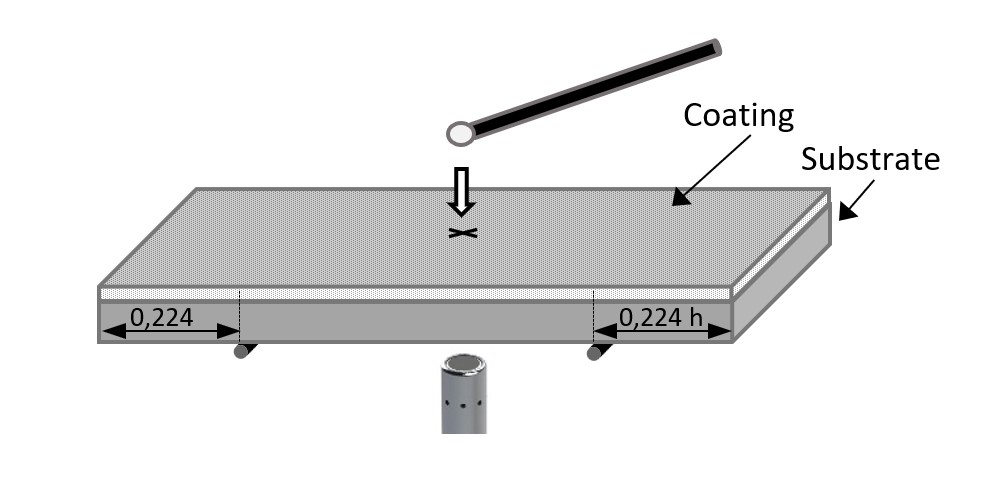

Employing the methodology described by Chiu and Case (https://doi.org/10.1016/0921-5093(91)90359-U) and by Tillmann, Selvadurai and Luo (https://doi.org/10.1007/s11666-012-9855-x), it is possible to determine the modulus of elasticity of coating layers applied on substrates by thermal spray. The images below illustrate the application of a coating via vacuum thermal spraying and the determination of the modulus of elasticity of a substrate plus coating via the Impulse Excitation Technique (Sonelastic®).

Sonelastic® Systems applications examples related to alloys, metals and coatings

Application: Characterization of coatings applied by thermal spraying for process optimization, elastic analysis and stress evolution.

Application: Characterization of coatings applied by thermal spraying.

Application: Metallic alloys elastic modulus characterization.

Application: Incoming inspection of titanium, steel and aluminum alloys; refinement of finite element analysis (FEA) of sonotrodes and power ultrasonic components.

Application: Characterization of metallic alloys for the refinement of finite element analysis (FEA) of sonotrodes and ultrasonic power components.

Application: Characterization of metallic alloys for the refinement of sonotrodes finite element analysis (FEA). Frequency analysis of sonotrodes and ultrasonic components.

Application: Characterization of the elastic modulus of metallic materials prepared via powder metallurgy and used in the manufacture of automotive systems. Refinement of acoustic resonance inspection criteria.

Application: Analysis of cast iron and shape memory alloys.

Contact person: Prof. Lioudmila A. Matlakhova.

Application: Characterization of the modulus of elasticity of steels.

Contact person: Prof. Dr. Mauricio Angeloni.

Application: Research and development of metal alloys and porous materials via powder metallurgy.

Contact person: Prof. Dr. Conrado Afonso and Prof. Dr. Claudemiro Bolfarini.

Application: R&D of metallic biomaterials produced via powder metallurgy.

Contact person: Prof. Dr. Vicente Amigó Borrás.

Application: Study of the correlation between vibration tests and finite element simulations of transmission system components.

Contact person: Eng. Fernando Luiz Windlin.

Sonelastic® Systems application examples related to alloys and metals

Borborema, S.; de Holanda Ferrer, V.; Rocha, A.d.C.; Cossú, C.M.F.A.; Nunes, A.R.V.; Nunes, C.A.; Malet, L.; de Almeida, L.H. “Influence of Nb Addition on α″ and ω Phase Stability and on Mechanical Properties in the Ti-12Mo-xNb Stoichiometric System”. Metals 2022, 12, 1508. https://doi.org/10.3390/met12091508

C. C. Bortolan, L. C. Campanelli, P. Mengucci, G. Barucca, N. Giguère, N. Brodusch, C. Paternoster, C. Bolfarini, R. Gauvin, D. Mantovani. “Development of Ti-Mo-Fe alloys combining different plastic deformation mechanisms for improved strength-ductility trade-off and high work hardening rate”. Journal of Alloys and Compounds, Volume 925, 2022, ISSN 0925-8388, https://doi.org/10.1016/j.jallcom.2022.166757.

J. Lario, Á. V. Escuder, F. Segovia, V. Amigó. “Electrochemical corrosion behavior of Ti–35Nb–7Zr–5Ta powder metallurgic alloys after Hot Isostatic Process in fluorinated artificial saliva”. Journal of Materials Research and Technology, Volume 16, 2022, Pages 1435-1444, ISSN 2238-7854, https://doi.org/10.1016/j.jmrt.2021.12.085.

M. R. da Silva, P. Gargarella, A. H. Plaine, J. Zeisig, S. Pauly, U. Kühn, C. Bolfarini. Microstructural evolution and properties of a Ti-Nb-Ta-Zr-O prepared by high-pressure torsion. Journal of Alloys and Compounds, Volume 864, 2021, ISSN 0925-8388, https://doi.org/10.1016/j.jallcom.2021.158828.

LEONARDO CONTRI CAMPANELLI, FRANCISCO GIL COURY, YAOFENG GUO, PAULO SERGIO CARVALHO PEREIRA DA SILVA, MICHAEL JOSEPH KAUFMAN AND CLAUDEMIRO BOLFARINI. The role of twinning and nano-crystalline ω phase on the fatigue behavior of the metastable β Ti-15Mo alloy. Materials Science & Engineering A (2018), https://doi.org/10.1016/j.msea.2018.05.069

PEDRO AKIRA BAZAGLIA KURODA, MARILIA AFONSO RABELO BUZALAF, CARLOS ROBERTO GRANDINI. Effect of molybdenum on structure, microstructure and mechanical properties of biomedical Ti-20Zr-Mo alloys. Materials Science & Engineering C (2016), doi: https://doi.org/10.1016/j.msec.2016.05.053

Guesser, W. and Martins, L., "Stiffness and Vibration Damping Capacity of High Strength Cast Irons" SAE Technical Paper 2016-36-0126, 2016. http://dx.doi.org/10.4271/2016-36-0126

Villalva, S., Gennaro, F., Windlin, F., Alegre, G. et al., "Study of Correlation between Vibration Tests and Finite Element Simulations by Means of Impulse Excitation Technique Applied to Components of an Automatized Transmission System" SAE Technical Paper 2013-36-0218, 2013. http://dx.doi.org/10.4271/2013-36-0218

Martins Júnior, J.R.S., Matos, A.A., Oliveira, R.C., Buzalaf, M.A.R., Costa, I., Rocha, L.A., Grandini, C.R., 2017. Preparation and characterization of alloys of the Ti–15Mo–Nb system for biomedical applications. J Biomed Mater Res Part B 2017:00B:000–000. http://dx.doi.org/10.1002/jbm.b.33868

D.R.N. Correa, P.A.B. Kuroda, C.R. Grandini, L.A. Rocha, F.G.M. Oliveira, A.C. Alves, F. Toptan. Tribocorrosion behavior of β-type Ti-15Zr-based alloys. Materials Letters, Volume 179, 2016, Pages 118-121,. ISSN 0167-577X. http://dx.doi.org/10.1016/j.matlet.2016.05.045

Discover the Sonelastic® Systems:

Sonelastic® system for small specimensSonelastic® system for medium specimens

Sonelastic® system for large specimens

Sonelastic® Custom System and quotation